Diagnostics

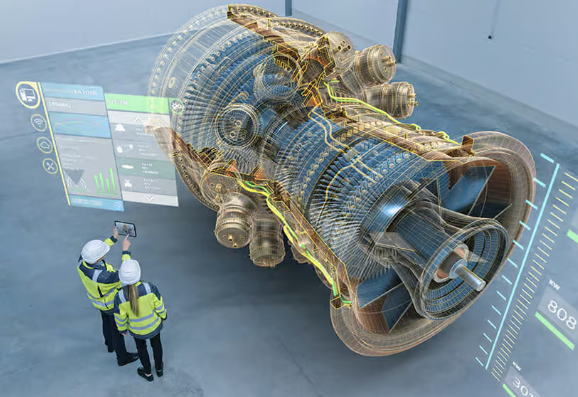

Roteq provides comprehensive diagnostics solutions to monitor and assess the health of rotating equipment. We help identify issues before they become critical.

Our services include vibration analysis, condition monitoring, and performance assessment to ensure machinery operates efficiently and safely.

We use advanced tools and techniques to detect misalignment, imbalance, bearing wear, and other potential failures early, minimizing downtime and repair costs.

Our team works closely with clients to provide actionable insights and recommendations for maintenance, repairs, and performance optimization.

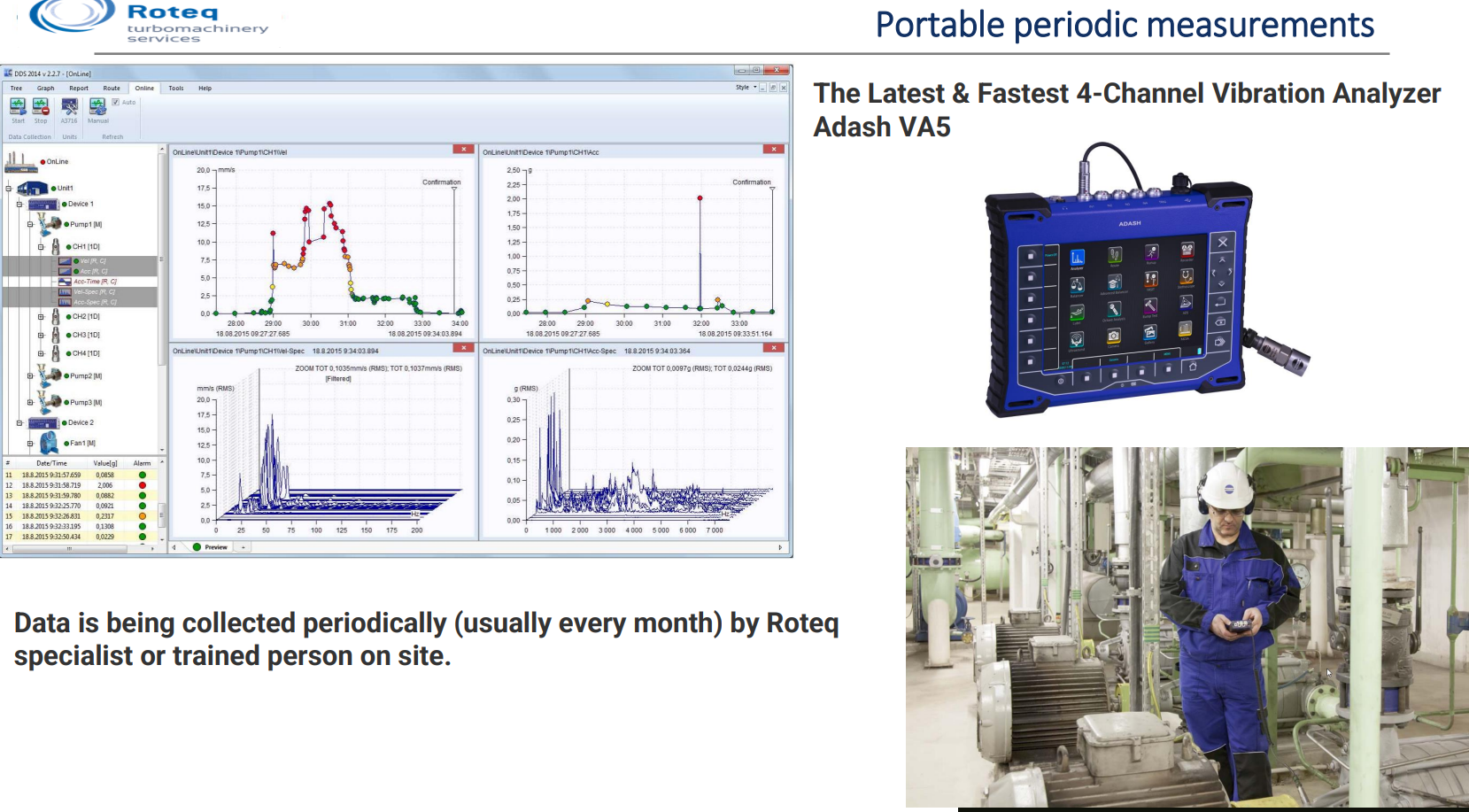

Vibration Analysis & Monitoring

Condition Assessment & Reporting

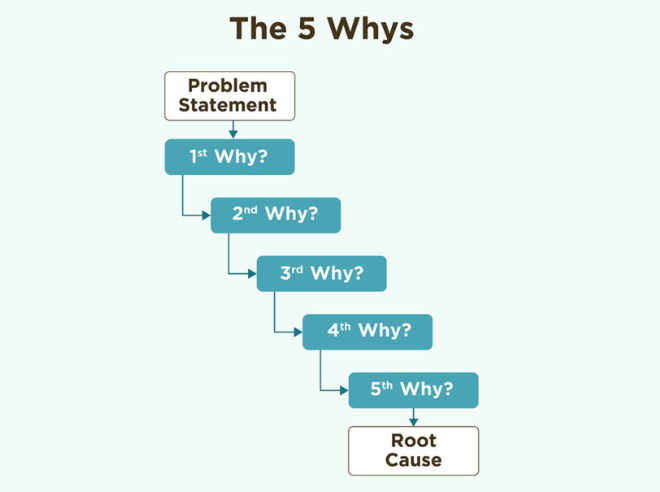

Root Cause Failure Analysis

Performance Evaluation & Recommendations

Roteq uses advanced vibration monitoring technologies to continuously assess the condition of rotating machinery. By analyzing vibration trends and patterns, we detect issues such as imbalance, misalignment, bearing wear, rotor instability, and other mechanical problems before they develop into major failures. This proactive approach supports predictive maintenance, minimizes unplanned downtime, and extends the lifespan of equipment. Our tailored programs deliver actionable insights, detailed data analysis, and practical recommendations for each client’s machinery.

We perform comprehensive equipment assessments using advanced diagnostic techniques such as thermal imaging, borescope inspections, and non-destructive testing. The findings are presented in clear, data-driven reports that describe the condition of the equipment, highlight critical issues, and provide practical maintenance recommendations. This approach enables clients to make informed decisions, plan maintenance efficiently, and improve overall operational performance.

When machinery failures occur, Roteq conducts thorough root cause investigations to determine the underlying factors. Our analysis considers mechanical components, lubrication systems, operational conditions, and historical performance data. By identifying the true cause of failure, we help prevent recurrence, enhance reliability, and reduce long-term repair costs. Our solutions are precise, actionable, and designed to strengthen equipment performance.

Roteq evaluates the overall performance and efficiency of rotating equipment, analyzing operational behavior, load conditions, and energy consumption. Based on these assessments, we provide tailored recommendations to optimize machinery performance, enhance reliability, and improve safety. Our guidance supports strategic maintenance planning, reduces operational risk, and ensures your equipment operates at peak efficiency over its lifespan.

How We Work

Top Working Process

Roteq's proven three-step approach ensures reliable turbomachinery solutions from initial assessment through to project completion. Our experienced teams deliver quality results on time, every time.

ASSESSMENT

EXECUTION

Delivery

Related Services

AUSTRALIA'S LEADING TURBOMACHINERY SERVICES

Discover our comprehensive range of turbomachinery solutions designed to keep your critical equipment operating at peak performance across all industrial applications.