Planned Overhauls

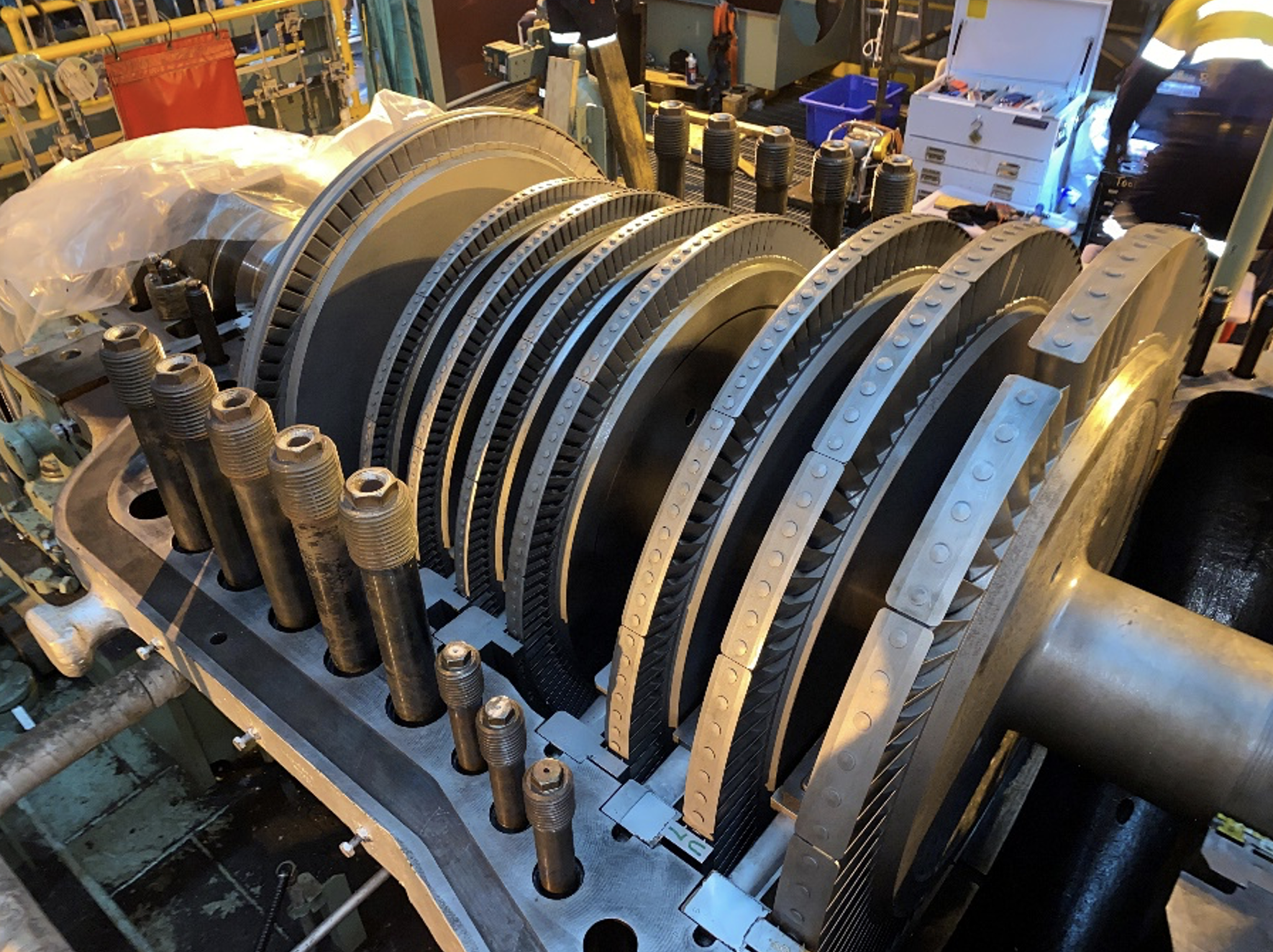

At Roteq, we specialise in the complete overhaul of rotating equipment, delivering safe, efficient, and cost-effective services that maximise asset performance and prevent unplanned downtime. Our planned overhauls are designed to minimise operational disruption while ensuring machinery operates at peak efficiency.

Our teams combine OEM-level expertise with advanced diagnostics, precision machining, and fully equipped repair facilities. Each overhaul includes thorough inspections, component refurbishment, and the installation of genuine or certified parts, with detailed reporting and testing to ensure complete safety, quality, and transparency.

How It Works

- Manage the entire shutdown process including resource allocation, spare parts, equipment, and task scheduling.

- Carry out full disassembly, cleaning, and precision inspection using advanced diagnostic tools.

- Perform component refurbishment and precision machining to restore equipment to OEM specification or better.

- Install OEM-approved or certified parts, followed by meticulous reassembly.

- Provide detailed inspection and test reports with photos, measurements, and recommendations for full transparency.