FS Elliott Centrifugal Compressors

Roteq is proud to be an authorized channel partner of FS-Elliott, a global leader in the design and manufacture of centrifugal air compressors. With over 60 years of proven innovation, FS-Elliott delivers reliable, energy-efficient compressed air solutions trusted by industries worldwide.

Through this partnership, Roteq provides customers across Australia with access to FS-Elliott’s full range of compressors, OEM parts, and technical expertise. By combining global technology with our local service capabilities, we deliver solutions that improve efficiency, reliability, and sustainability for industrial operations.

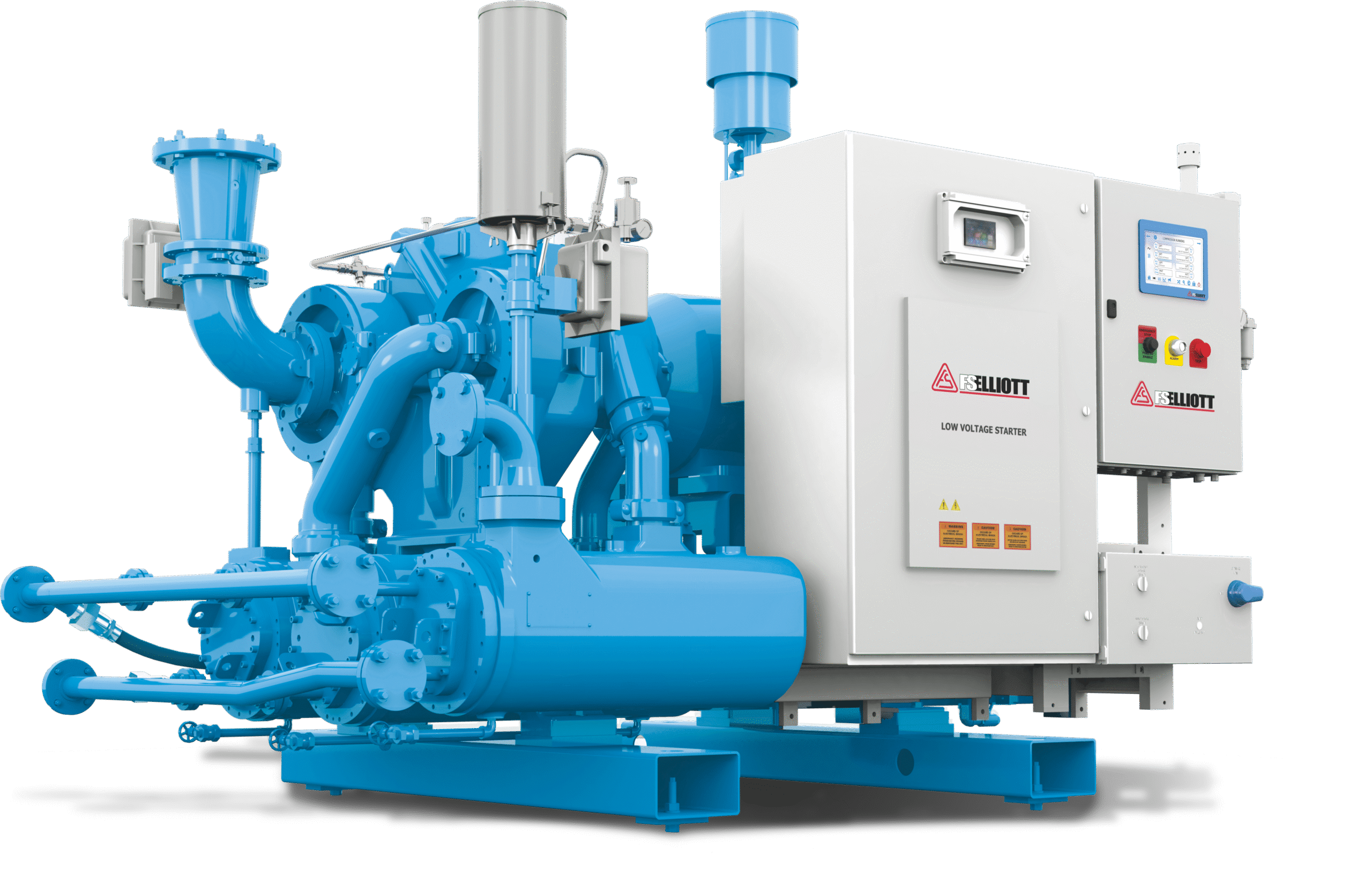

FS Elliott Polaris® Series

FS-Elliott’s Polaris® industrial air compressor series combines over 60 years of operational and design experience in an extremely reliable, energy-efficient, cost-effective package. They suit a broad range of applications, with models ranging from 250 hp to 3,000 hp in two and three-stage configurations that deliver up to 250 psig (17.2 barg) discharge pressure.

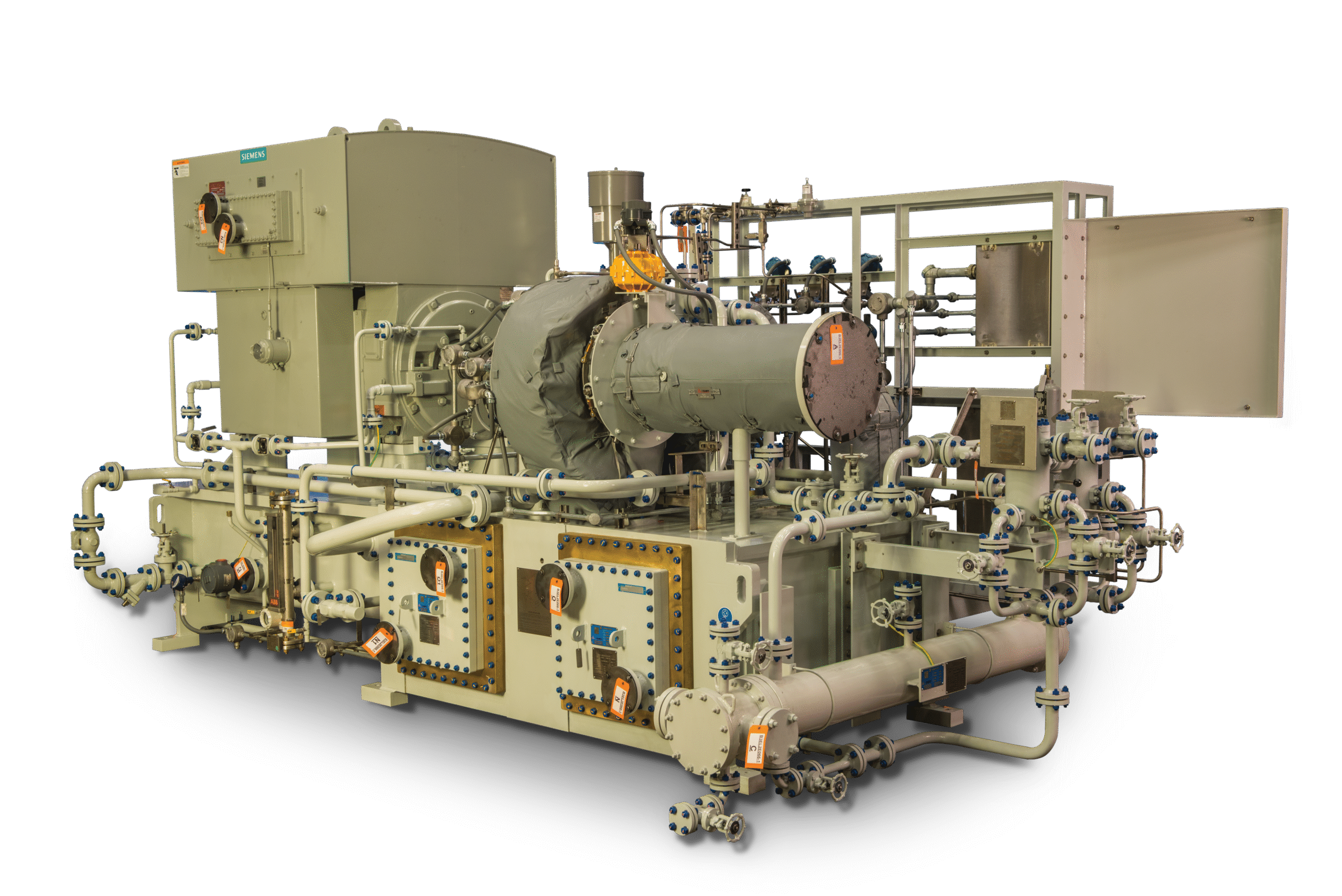

FS-Elliott’s PAP Plus® engineered compressor

FS-Elliott’s PAP Plus® engineered compressor series combines over 60 years of operational and design experience in a highly robust, uniquely easy-to-maintain package. They suit a broad range of applications, with models ranging from 120 kW to 4,475 kW or 160 hp to 6,000 hp in one, two, three, and four-stage configurations that deliver up to 31 barg or 450 psig discharge pressure.

Advantages of Centrifugal Compressors

Centrifugal air compressors also referred to as dynamic compressors, are designed to produce large volumes of compressed air in an extremely energy efficient process. Although manufacturers that require over 200 to 250 total horsepower tend to realize the greatest savings, all industrial manufacturers should consider the advantages of centrifugal technology.

Oil-Free Compressed Air Stream

Centrifugal compressors eliminate the risk of oil contamination in product lines and equipment, significantly reducing maintenance requirements and downtime. The oil-free condensate generated is not subject to strict disposal regulations, allowing for easy and cost-effective waste management.

Fewer Maintenance Requirements

Centrifugal compressors feature non-wearing compression surfaces for longer-lasting components and drastically reduced oil and filter requirements, saving both material and labor costs. FS-Elliott's horizontally split gear case design allows full field access to the gearbox, eliminating costly downtime for maintenance.

Increased Energy Efficiency

Available in up to four stages, centrifugal air compressors are on average 5% more efficient than older compressor designs. As the number of stages increases, the compression ratio is lower, meaning higher efficiency.

Get Your Next Compressor!

Local Expertise with Global Technology

As an FS-Elliott channel partner, Roteq not only supplies genuine compressors and OEM spare parts but also provides

- Expert installation and commissioning

- Preventive maintenance and on-site service

- Diagnostics and performance optimization

- Rapid access to OEM engineering support

By partnering with FS-Elliott, we combine advanced compressor technology with local engineering expertise to help our customers achieve reliable, efficient, and sustainable operations.