Achieving a successful overhaul begins with careful planning well in advance. Roteq’s pre-shutdown planning provides a clear understanding of the scope, resources, and timelines required, giving you greater predictability for both cost and schedule.

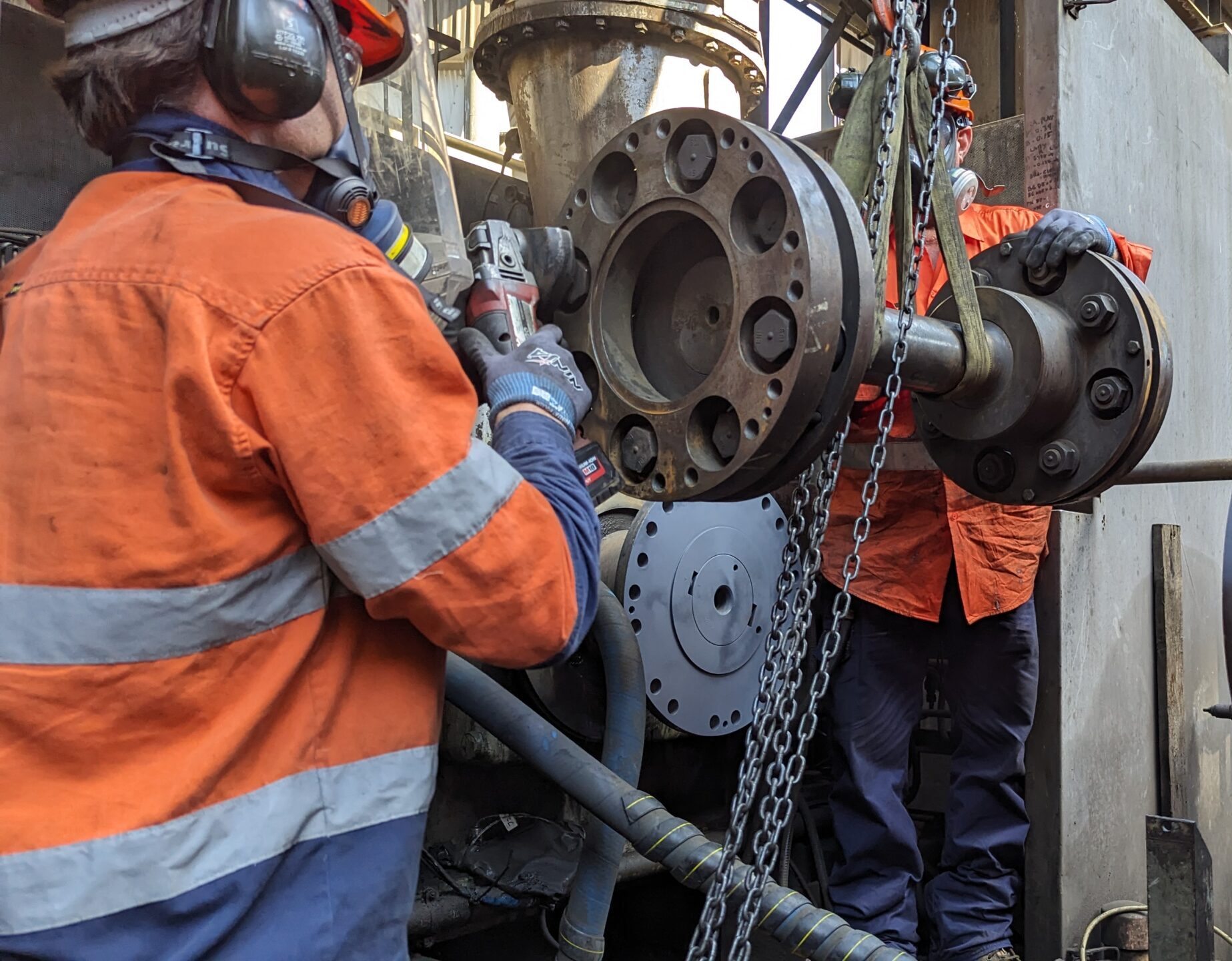

Our team works closely with your operations and maintenance teams to define the detailed scope of all rotating equipment involved in the planned overhaul. This early involvement ensures that every step of the process is coordinated for maximum efficiency and minimal disruption.

Serviceable spare parts are critical to the success of any rotating equipment overhaul. Roteq conducts a thorough on-site inspection of your stocked spare parts, producing a detailed report with recommendations for repairs and identifying any stock shortfalls.

By ensuring that the right components are available when needed, we help prevent delays and support the smooth execution of your overhaul. This proactive approach enhances operational reliability and protects the longevity of your critical machinery.